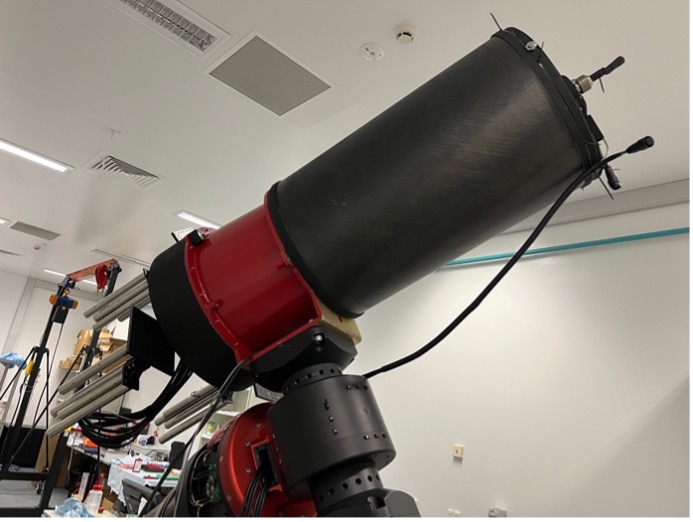

Enter New Frontier Technologies (NFT), a start-up company run by former ANU academic and researcher, Dr Paul Compston. NFT is based within ANU’s Momentum Industry Hub and specialises in creating advanced carbon composite structures for high-performance applications. NFT took on the challenge issued by DREAMS project lead, Professor Tony Travouillon, to develop a load-bearing and mounting structure for the primary and secondary mirrors of the telescope – one that could remain stable over a wide range of temperatures changes and easily manage the weight of the equipment placed upon it.

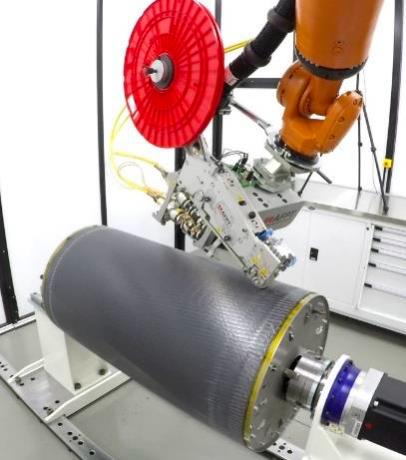

Fortunately, NFT’s ability to create a custom carbon composite material proved to be perfect for DREAMS. Dr Compston and his team developed a structure with a zero coefficient of thermal expansion (zero-CTE) for the primary and secondary mirrors, meaning that the material would not shift or expand when confronted by changes in temperature. NFT’s design and additive manufacturing (3D printing) capability also allowed them to ensure stability over a wide temperature range to eliminate the risk of de-focusing during an observation. This was achieved by using laser-assisted automated fibre placement (laser-AFP) that precisely placed carbon fibres in the directions required to achieve the specified performance, which was zero thermal expansion in the axis of the primary and secondary mirrors. Dr Compston and his team were also able to match the radial CTE of the composite structure with the aluminium mounting rings for the mirrors, ensuring movement could occur where it was needed but only in specific places. This customisation is a game-changer for astronomers, as the metallic materials traditionally used to construct ground-based telescopes cannot be tailored in the same way and are prone to thermal expansion and contraction.

NFT also made sure that their composite structure was lightweight, which was a necessary requirement to keep DREAMS agile and put less stress on the rest of the telescope structure and systems. With a total weight of 8kg, NFT’s composite structure came in at less than half of the 20kg target weight. The process of manufacturing was also incredibly fast. The team at NFT were able to create the structure for DREAMS in 8 hours using their automated (robotic) manufacturing technology – very quick when compared to traditional thermoset (epoxy) based carbon composites. These composites are labour and energy-intensive and it would take several days to manufacture an equivalent structure.

Professor Travouillon was very impressed with the results, noting that the output of this work could be multiplied in other areas where astronomy instrumentation builders still have a large impact on the market.