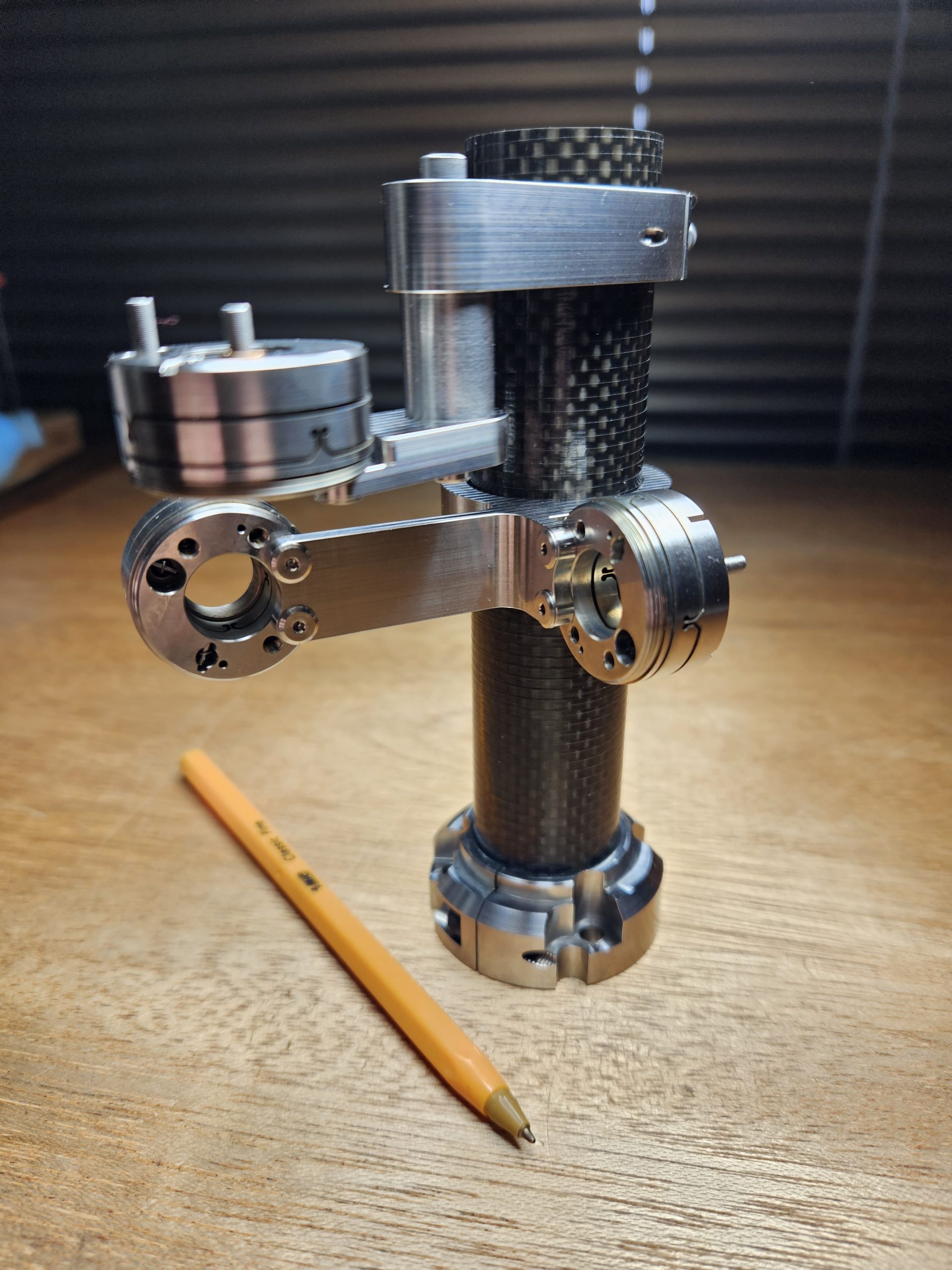

An example of this can be seen with NH Micro’s recent work building an essential component for a new beamline at Australia’s Synchrotron. The Synchrotron is an advanced scientific facility based in Melbourne’s outer suburbs, owned and operated by Australia’s Nuclear Science and Technology Organisation (ANSTO). The synchrotron uses magnets to accelerate beams of light around its enormous ring-like structure. As they approach the speed of light, the beams are directed into structures, known as beamlines, similar in size to shipping containers that sit just outside the rings. Various beamlines collect different types of energy, from x-rays to infrared beams, focusing them toward samples that are being studied for scientific research. In close collaboration with synchrotron scientists, Hacko and his team built a robot to position samples within a beamline currently under construction – a job he describes as his most complex to date.

While ANSTO presented a unique challenge, they also proved how well NH Micro can adapt to suit their customer’s requirements. Including ANSTO, the NHW group currently lists 150 clients, with 90% of those added since the creation of NH Micro. This year, approximately 50% of total revenue for the group came from the NH Micro arm alone. Between both companies, 11 people are employed – four of which are working full time for NH Micro. Not bad for a company that only started operations in 2020. The group has also been able to reinvest all profit from the NH Micro side of the business into their workshops, capability, staff, and development processes – what Hacko calls the “journey of precision manufacturing”. This equates to about $1M a year going back into the business. Without NH Micro, Hacko is certain that this scale of reinvestment wouldn’t be possible.

Coming full circle, NH Micro recently teamed up with another group of astronomy instrumentation builders – Australian Astronomical Optics (AAO) at Macquarie University. The project is part of a collaboration between AAO and lead partner, Advanced Navigation, who are set to deliver a sensor called LUNA (Laser measurement Unit for Navigational Aid) to US-based space systems company, Intuitive Machines. Part of NASA’s ongoing Commercial Lunar Payload Services program, Intuitive Machines will mount LUNA onboard its Nova-C lander, slated for a mission to the moon in the next couple of years. LUNA’s sensor, using AAO’s focused multi-beam optical laser device (known as a collimator), will allow the lander to safely touch down on the moon without any real-time assistance from mission control.

Hacko was introduced to AAO’s project leader, Lee Spitler, at an Astronomy Australia Limited (AAL) Industry Engagement workshop in November 2023. Spitler recognised the skill and adaptability of NH Micro when he saw Hacko present during the event. As a result, NH Micro is now handling the precision machining and optical head assembly that will be used by AAO to build the collimator for LUNA.

If this wasn’t enough, there is also more work on the horizon for NH Micro. Larger government bodies are becoming very interested in their capability, which Hacko puts down to the fact that this capability has not existed in Australia for a very long time. He notes that the history of precision engineering and manufacturing in Australia can be traced alongside large industry trends. The automotive industry, for example, generated a lot of precision manufacturing. As did the gambling industry, with the manufacture of pokies machines. When these industries left Australia, or the requirement for manufacturing was replaced by computer software (in the case of pokies machines), that precision engineering disappeared as well. Hacko explains that these capabilities don’t exist out of thin air – there has to be a need.